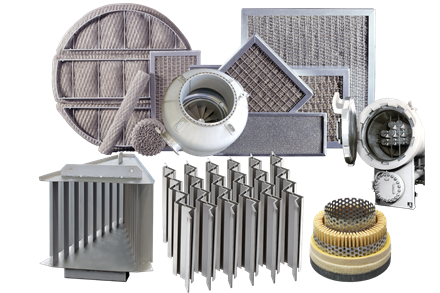

除雾器

Cold Side Packs

Other Mist Eliminators

产品介绍

The reheating of treated flue gases from the scrubbing tower, before discharge to the stack, plays a vital role in the operating costs of flue gas desulphurisation plants (FGD) working on wet processes. The operating conditions in FGD plants are generally highly corrosive and have a high scaling tendency, which could cause high maintenance and replacement costs of the GGH or parts of them. Depending on the operating conditions of the FGD and the GGH, it makes sense to install a totally corrosion-resistant plastic separation element at the cold side. This C-pack may be used when a high liquid load or fly ash content in the treated gas is expected, e. g. due to continuous water washing

of the booster fan. The plastic surface properties prevent a bonding of deposits to the material and the high expansion coefficiency and the vibrations of the single plates cause a (self-cleaning) effect. C-pack extends both the service life of the GGH and also prolongs the interval between servicing. In doing so it reduces losses in energy output caused by constant growth of pressure drop and also contributes to improved downstream performance and overall process stability. Typically, the enameled heating elements are washed with air or water pressure of 80 bar and more. Due to this high pressure the enamel surface, especially the sharp edges facing the cleaning devices, will be damaged.

Additional manual cleaning with high pressure cleaning devices also causes damage to the surface of the heating elements. The Munters C-pack protects the heating elements from the hard treatment thereby increasing the lifetime of the whole GGH system. Munters can supply either full-scale erection services or – as an alternative – offer the assistance of a qualified and experienced supervisor for the erection carried out with local personnel, according to the customer’s requirements.