CPS changes climate with Quantum & Power Purge

The benefits of Munters Quantum-rotor and patented Powerpurge systems were seen immediately by CPS – part of the Tetrapak Group for their latest fluid bed drying application. CPS have installed a stainless steel 20,000m3/h Munters MDU system capable of going from 18g/kg to 2g/kg in one step – a major achievement for CPS. CPS supply dairy, cheese and powder processing systems and see the "No Wet Surfaces" capability (as it avoids pre-cooling) as a major benefit in increasing hygiene. The Quantum-rotor enables a big dehumidification capacity to be created i.e achieve a low process air moisture content using only a single step, so eliminating the need to pre-cool. In many industries, drying is based on conventional heat and vent, this has one common harmful drawback: The drying process effects product quality due to outdoor climate and seasonal variations. With Munters Quantum technology, applications such as a spray-drying benefit in a reduction of absolute moisture content whilst increasing the process air temperature.

HACCP-Food grade

Risks for mould growth and bacteria developing in critical locations has to be avoided. Whilst condensation cooling with wet surfaces may have been accepted in the past, food processors now reject this approach in favour of "Dry" processing. With Munters approach, cooling equipment is now superfluous as the Munters GTR rotor can do the job, so increasing Munters opportunities in these applications.

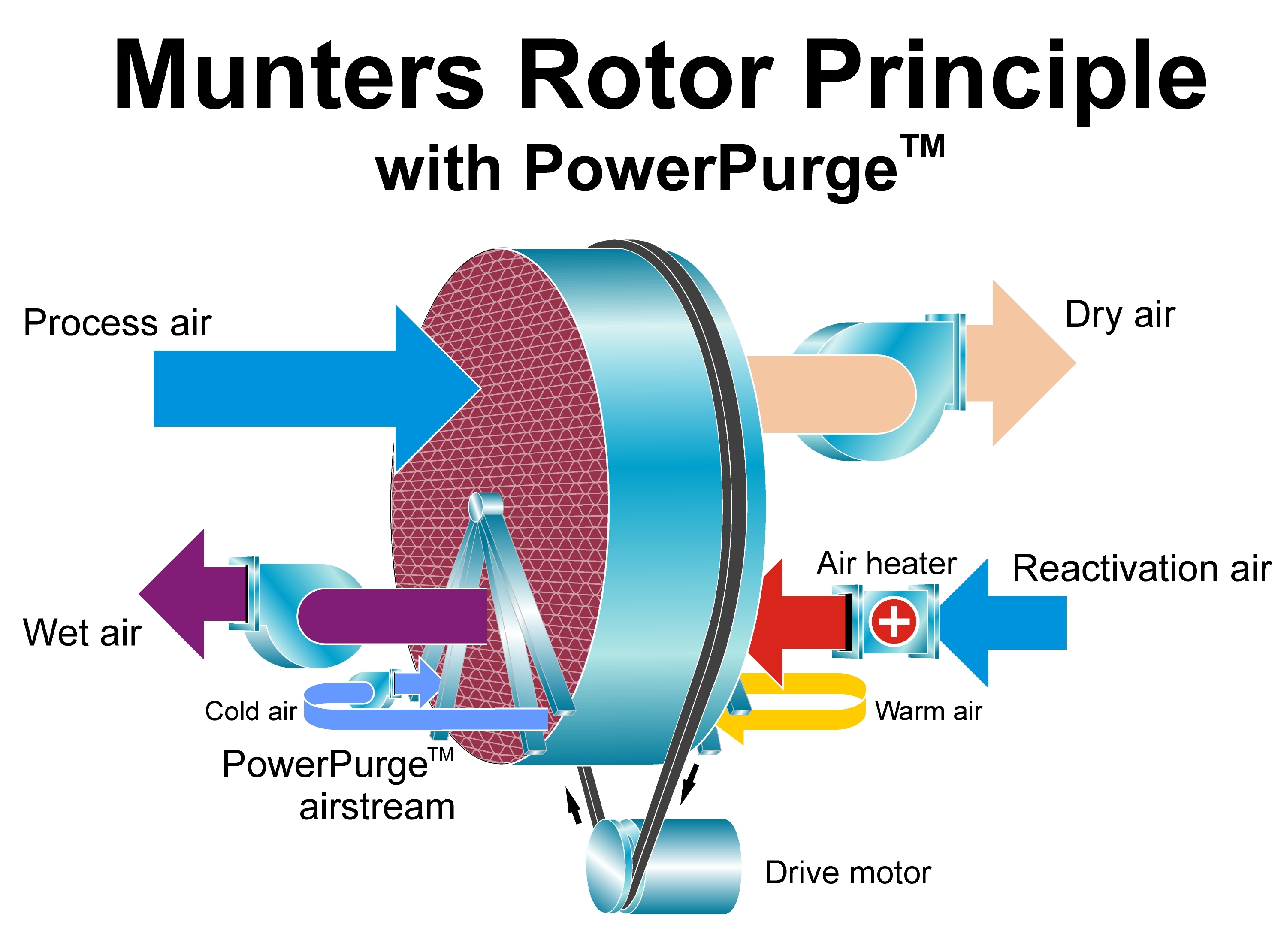

Cooling process – PowerPurge

The temperature increase due to dehumidification of the process air outlet is not always welcome and can now be reduced using Munters new patented PowerPurge. Sensible heat is transmitted from the reactivation outlet sector into the reactivation inlet sector and simultaneously the heat load to the after cooler is reduced by the same amount. With the PowerPurge the COP of the cooling equipment can be improved-meaning less consumption of expensive power. Everyone talks about the weather, but who changes it? Munters changes the climate and contributes to World CO2 reduction.