Sorting, Weighing, Mixing, Filling

Food production processes such as accurate sorting, dosing, weighing, mixing or filling are all sensitive to high relative humidity and its negative effects.

Condensation can cause products to clog together blocking of sorting or multihead weighing machinery. Weighing can become inaccurate when products unintentionally absorb ambient humidity.

Munters dehumidification efficiently controls and limits the humidity, so:

Secures reproducible scaling processes

Keeps sorting and mixing processes free from condensation and related blockages eg. multi head weighing machines

Prevents sticky products (confectionery, vegetables, cheese etc) blocking machinery

Increases accuracy in dosing, mixing, weighing processes

Reduces costly cleaning caused by unplanned production stops

Improves hygiene as low humidity inhibits growth conditions for microorganisms

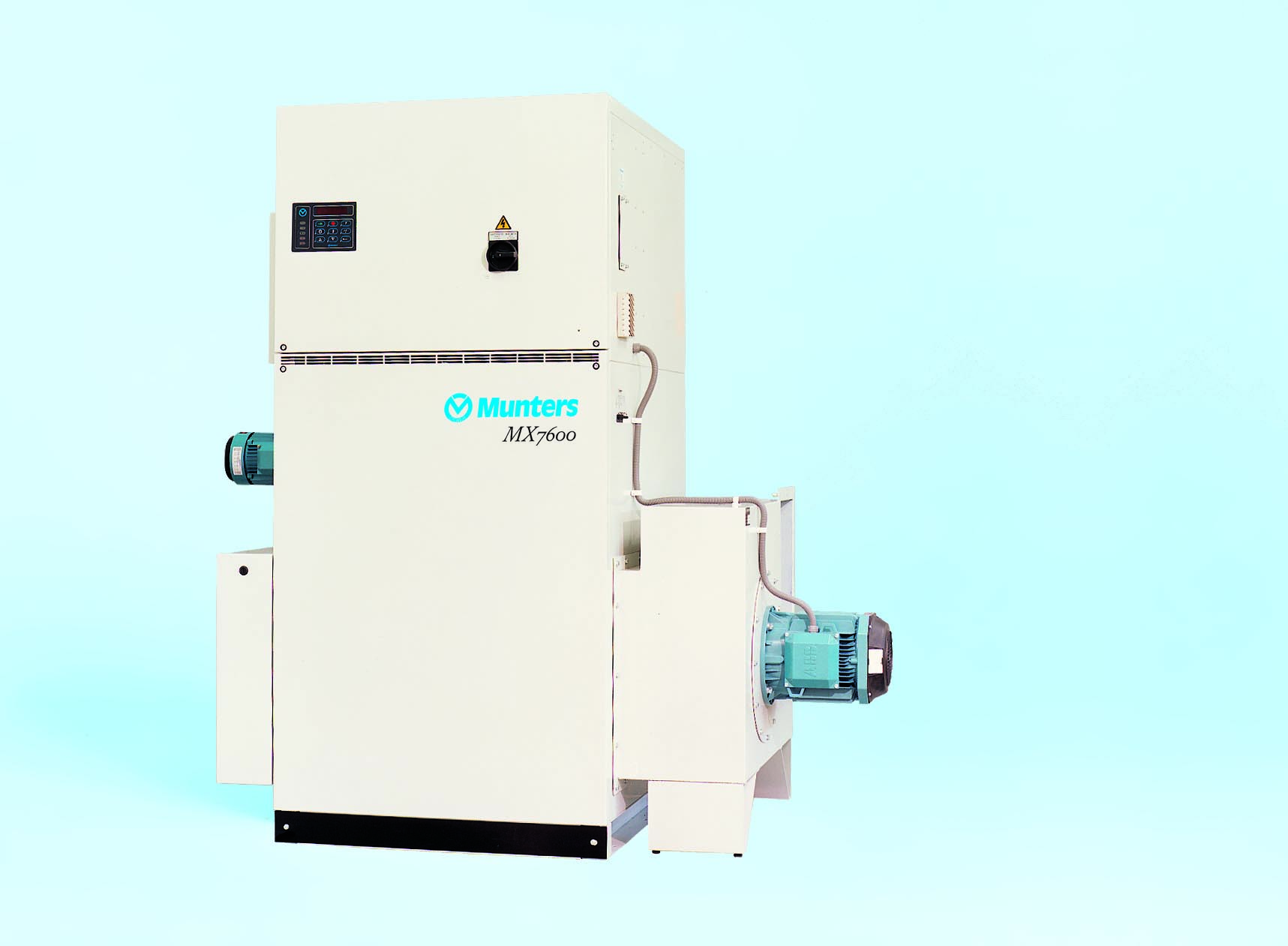

Humidity control using Munters desiccant dehumidifiers can focus on an individual production line or machine or the complete production room. Low and controlled humidity will reduce the disruptive influences of condensation formation.

Read more on how Munters improve manufacturing conditions at: Unilever (Filling machines, frozen peas)

Ardo (mixing and packing of frozen vegetables)