Systems Munters dry air to improve maturation of Chorizo

The manufacturing process of the sausage is formed by various processes, combined properly, result in products with unique and very special textures ingredients.

The complex manufacturing process and any meat sausage product is influenced by factors such as water and various microorganisms which affect the maturation and, therefore, the characteristics of the product.

The components of sausage chopped is mixed homogeneously, to become, in what is commonly called a chorizo sausage, after maturation in several phases.

A key part of this process is the drying. At this stage, the product loses between 25 - 35% of its weight in water. The drying is very important for the shelf life and flavor.

The traditional drying system

In the process of maturation of the chorizo, you need to use rooms maturation and drying with air flow control, temperature and humidity. In traditional systems, the required ambient conditions (approximately 18-22 ° C at 60-70% relative humidity) are achieved by heating and cooling the air in a closed circuit.

A ventilation system and air distribution creates an air circulation more or less uniform in the room. But these systems are insufficient to create the necessary conditions for the ripening process.

In winter, the air outside is drier compared to the summer, where the air has higher moisture levels. In this season, the drying capacity is not enough and the product is dried very slowly. This prolonged exposure of the product in a moist environment, often causes the growth of microorganisms on the surface of the sausage which is deterioration of the product and, therefore, an economic loss.

The most advanced technology systems Munters dry air

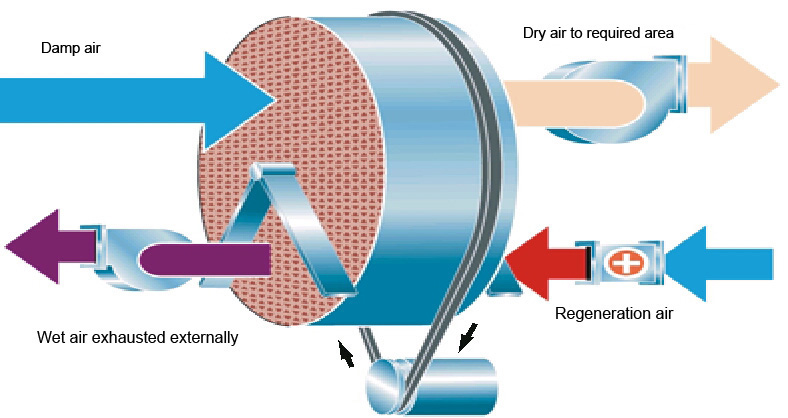

The Munters dehumidification systems maintain desired humidity conditions independently of external climatic conditions by acceleration of the drying process with greatly reduced energy costs.

After several meetings between manufacturers and experts from Munters to search for new alternatives, this advanced and cost efficient solution emerged.

The Munters dehumidification system was designed to be installed near the ripening room through an air inlet and an air vent.

The Munters dehumidification systems controlled by a humidity sensor that measures the level of humidity in the ripening room and ensuring the maintenance of the desired humidity level.

Munters dehumidifiers can have electrical recovery, gas or steam. The resulting savings is in relation to the size of dehumidification equipment and associated energy costs.

The concept developed by Munters reaches its full capacity operating in a very short period of time because it is easy to implement and supports optimally the existing process.