Munters lowers reject rate in fruit labelling

Stickers or labels attached to fruit speed up scanning process at the store checkout however, many fruit companies hear complaints about stickers that fall off during transport.

In response companies are experimenting with different sticker materials and labelling under a variety of temperature and moisture conditions. Kiwi's are conserved in refrigerators at a temperature of 5°C. They are collected from the refrigerator, selected and controlled. This procedure ensures the best quality fruits are retained. After this, the product is transported to the conveyer belt of the labelling machine, where all the kiwi's get a sticky label with the logo of the producer. Then the kiwi's are packed and sent to the various supermarkets and stores.

Before collection the kiwi's, are checked and to ensure they have a quality label attached. Kiwi's without a label go through the labelling process again, to avoid rejects from the customer. Retailers will not accept kiwi's without a label and generally have a maximum acceptance threshold of 5% per supply without labels.

Kiwi's which come directly from the refrigerator, tend to have condensation on their surface which make it difficult for the labels to adhere to the fruit. As many hundreds of kiwi's are labelled a minute, the adhesion issue requires extra costly control, taking added time and time is money.

At Italian producer Intesa Imola Munters solved this problem with their desiccant dehumidification process. First a tunnel was created to isolate the climate surrounding the conveyer belt before the labelling process. Inside the tunnel a desiccant dehumidified airflow is transported from a Munters dehumidifier supplying 5,000m3/hr. In this way, the surface of the kiwi's becomes dry immediately prior to arriving at the labelling machine. The labels attach better and last but not least, the kiwi's do not lose their labels further in the process. The fresh fruit cannot be reworked indefinitely without becoming spoiled.

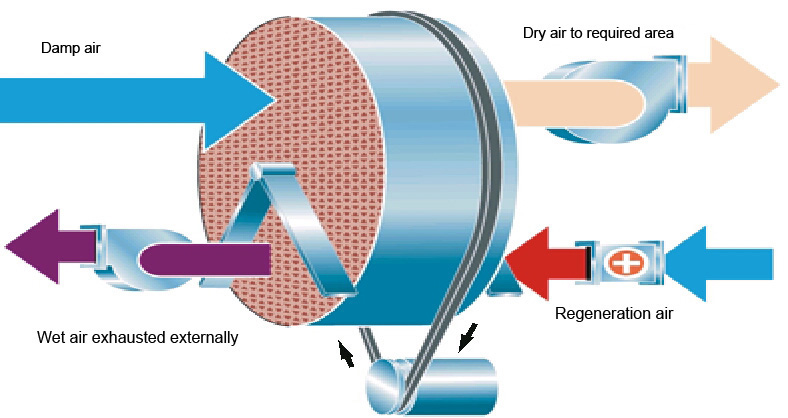

The principle of Munters dessicant dehumidifiers is very simple. Moisture is absorbed onto a slowly-revolving dessicant wheel as the air passes through. In another air-stream the moisture which has collected on the drying side of the dehumidifier is driven off the wheel. This is vented outside the tunnel.