Dehumidification solution to control humidity in Claxton Poultry

In the food industry, the presence of liquid water is a factor extremely important for bacteriological contamination. An uncontrolled presence of water sources is the condensation on the cold parts of the production process.

The Problem

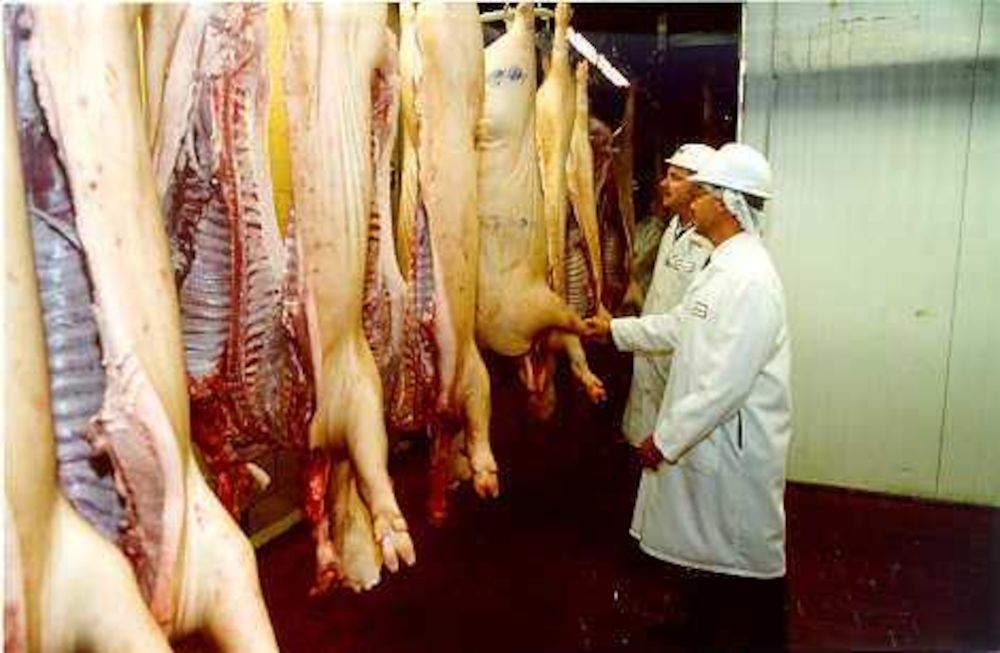

Large amounts of water are used by poultry processors to maintain a sanitary work environment. This water evaporates and condenses on ceiling, walls and equipment within processing areas. The presence of condensation resulted in a warning letter from the USDA in the fall of 2003. Per USDA FSIS directives condensation is not allowed to form either in product or non-product areas, where the potential for dripping can occur; causing contamination of product. For many years the problem had been addressed by using plastic sheeting hung from the ceiling and personnel that are dedicated to wiping away condensation as it formed. This proved to be a time-consuming and costly solution that does not control condensation to meet with USDA compliance. Claxton contacted Munters for a dependable, cost-effective solution.

The solution

A quick response was required to prevent any production downtime due to condensation. Munters provided a temporary Condensation Control System (CCS) to solve Claxton’s condensation related problems. These systems can typically be provided in 24 to 48 hours to meet a customers immediate dehumidification needs. The CCS works by supplying dehumidified air that absorbs moisture and controls the formation of condensation. The CCS consisted of desiccant dehumidifiers, cooling modules and chillers.

The condensation began to disappear within hours of the equipment installation. “The Munters equipment has allowed Claxton Poultry to operate without condensation- related NRs,” said John Seibel, complex manager at Claxton. The USDA warning letter was lifted after 90 days of operation without receiving an NR (Non-Compliance Record). Claxton has seen other benefits of using dehumidification. A significant number of workers were dedicated to wiping away condensation and installing plastic sheeting. These workers are now able to perform other functions within the facility reducing labor costs. Sanitation has been improved within the plant because with dehumidification operating Claxton has been able to run sanitation right up to shift start. This allowed “on time” shift starts which has improved production management. Defrost cycles on existing cooling equipment have been reduced from four to once per day because desiccant dehumidification delivers air at lower dewpoint temperatures.

Claxton Poultry installed permanent Munters Condensation Control Systems in the eviscerating and further processing areas in 2004 to prevent condensation and is evaluating other areas within the plant.