Dehumidification prevents downtime in food preparation - Kreatina A/S

Skånekött AB Kreatina A/S refines charcuterie products for the retail and catering in Denmark and Sweden. Kreatina A/S in Bjæverskov, Denmark, carries out cooking, smoking, salting and freezing of the products.

For several years Skånekött AB in Sweden has been using dehumidification from Munters with great satisfaction. Kreatina A/S therefore also turned to Munters to solve problems with downtime caused by moisture in the electronic control panels.

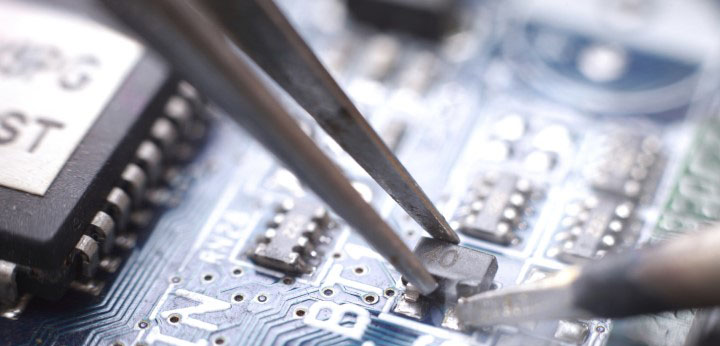

The factory uses large amounts of water during production in daytime. In the evening hours a large volume of water is used for thorough washing and rinsing of the rooms and production machinery. These amounts of water increase the relative humidity in the production rooms to a very high level. The different production lines are all controlled via electronic/ digital control panels and as all other electronics these controls are sensitive to high humidity. At least once a day Kreatina A/ S experienced one production interruption caused by moisture in these control panels. Such an unplanned stop meant that production was suspended for 1-2 hours.

Munters developed a solution where 4 dehumidifiers type ML1350 were installed on the roof of the production halls. Each dehumidifier supplies dry air to one room - each room is about 900m3 and the temperature is respectively 6 ° C and 12 ° C. The operation of the dehumidifiers is controlled by a built-in electronic humidistat, which ensures that the humidity in the production rooms now never exceeds 60% RH. The premises are now dry in the morning after the night's cleaning and washing down and since the installation Kreatina A/S has not experienced a single stoppage caused by moisture in control panels. The lower and controlled humidity also means that the risk of mold and mildew growth on walls and ceilings disappeared and furthermore the less humid work environment is perceived as an improvement for the staff.