Woolworths RDC

The Project

"Quality and freshness doesn’t come easy, which is why some 616 people work around the clock at Woolworths’ Perth Distribution Centre to tackle the mind boggling logistical challenge of coordinating supplies from the farm-gate to supermarket shelves across the state. The 81,500 square metre DC is the hub that links Woolworths’ network of farmers to its 85 WA stores, from Broome in the north to Esperance 2910km to the south.

There are three quality controllers who randomly check the contents of all deliveries – a big task given that just over 24,000 cartons go through the DC daily. That equates to 170,000 cartons of fresh food per week or 8,840,000 each year."

Munter's Contribution

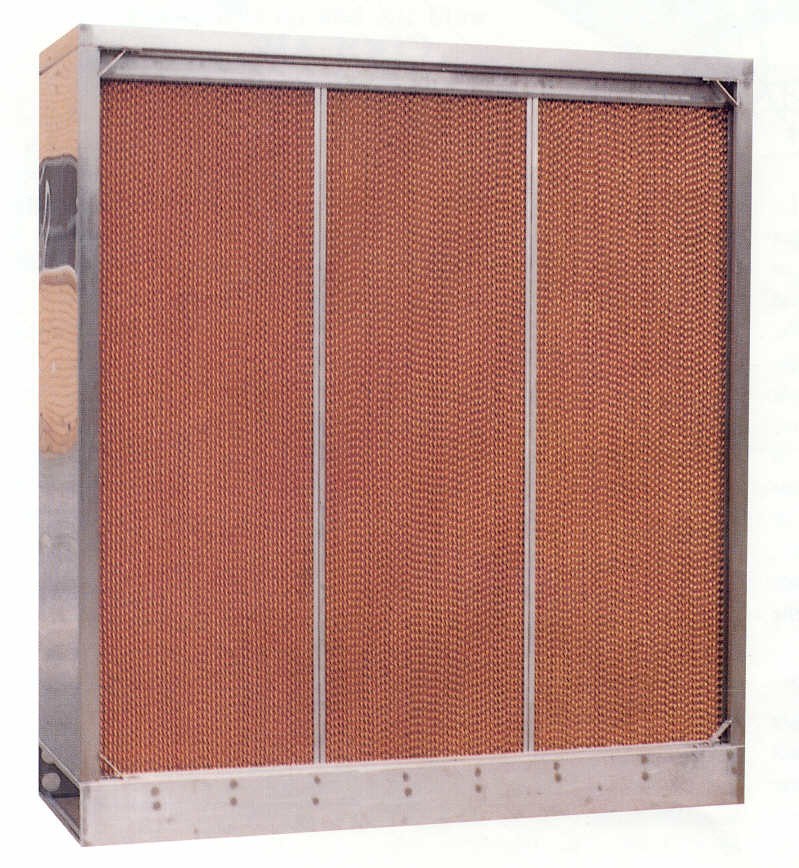

Perth was the first of six (6) Woolworths RDC’s Munters were involved with, our engineers assisted in the base design to find a solution to the stringent requirements of controlling three (3) separate spaces at 2°C, 7°C and 12°C while maintaining humidity at 95 %. Munters were engaged by BECA consulting group to provide the model “MHI” series of evaporative humidifiers to be installed directly into the refrigeration penthouse units (Penthouse units are above ceiling refrigeration air handling units) to provide humidity directly to the air handlers to combat the drying effect of all the cooling taking place. Air passing through the CELdek® pad is humidified and cooled due to intensive contact between the air and the wetted unheated pad surface. The increase in humidity occurs through evaporation alone, without the need for additional energy input. Only a small amount of water is consumed. The water, either being circulated from the water reservoir or connected to the mains water supply is distributed over the top and falls by gravity through the CELdek® pad and is collected by a sump below.